Aggregate Making Hammer Crusher In Cement Plant

The hammer mill is mainly composed of shell, rotor, hammer, bar and so on. The box is divided into two parts: the upper and lower parts are connected by welding and cutting steel plates. The other parts are connected by screws. The inside of the box is high manganese steel liner, which is easy to replace when worn. There are several hammers on the spindle, which consist of rotor and turntable and wear hammer shaft. It rotates through the motor and V belt to drive the spindle and rotor to make centrifugal force diffused from the hammer. Then the large material is put into the crushing chamber and broken by high speed hammer. After these treatments, the standard material is screened out by the lower bar, and the non-standard material is broken again in the crushing chamber. In order to avoid clogging, the humidity of broken materials should be less than 10% to 15%.

Application of Aggregate Making Hammer Crusher In Cement Plant

Applied in the crushing and fine crushing of medium-hard materials in cement,chemicals,electric power,metallurgical industries,etc,such as limestone,slag,coke,coal and other materials. Crumble the materials of the size 60 to 180 mm into 25mm or 25mm below. To crush various materials with compressive resistance under 150Mpa. Working Principle of Aggregate Making Hammer Crusher In Cement Plant

The motor drives the rotor to spin at high speed, materials are fed into the crushing cavity evenly , and the materials could be impacted, cut and tore by high speed spinning hammerhead till they are crushed completely. Meanwhile, the gravity action of materials forces them to crash the baffle and grate bars on the frame. Materials with particle size smaller than the screen size will pass the sieve plate while those with bigger particle size are stopped on the plate and will continue to be impacted and grounded by the hammer until they are crushed to the required particle size, finally, crushed materials will be discharged from the hammer crusher through the sieve plate.

Features of Aggregate Making Hammer Crusher In Cement Plant

The rotor is strengthened by finite element analysis. High crushing ratio. The crushing ratio is 10~25 or even higher to 50. The stone impact theory effectively reduces the wear load of hammerhead and grille plate. The sealing structure solves the problem of dust pollution and leakage in the crushing workshop.

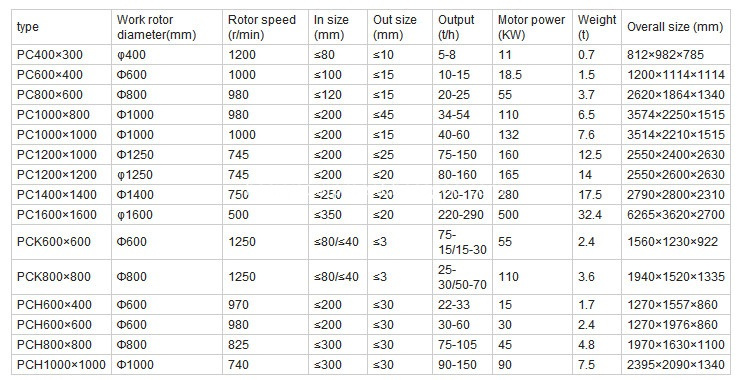

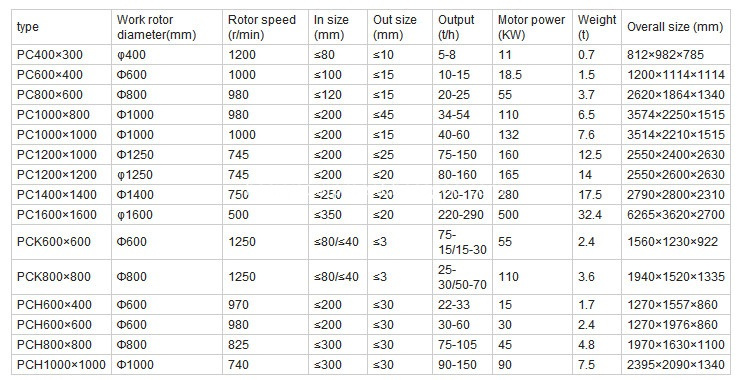

Specification of Aggregate Making Hammer Crusher In Cement Plant

Compay Information

Henan Mingyuan Heavy Industry Machinery Co., LTD is one high-tech enterprise, which involves R&D, manufacturering, sales and service as well. In the past 20 years, we devote ourselves to producing mining equipments such as Aggregate Making Hammer Crusher In Cement Plant, jaw crusher, fine crusher, impact crusher hammer mill crusher, vsi sand maker, cone crusher, sand washing machine( both wheel type and spiral), rotary dryer, ball mill, rotary kiln, cement ball mill, magnetic separator, belt conveyor, shaking table, spiral chute, and so on. In recently years, we have developped our business in new areas, such as grain dryer, waste material recycling plant for waste tyre, rubber, bottle, and so on. for all equipment we provide we can send our experienced engineer to your workshop to guide the installtion until the whole plant works normally.

Our Services of Aggregate Making Hammer Crusher In Cement Plant

1. Pre-sale services: Act as a good adviser and assistant of clients. (1) Select equipment model; (2) Design and manufacture products according to clients' special requirement; (3) Train technical personnel for clients; 2.Services during the sale: Respect clients; considering every aspect and details for our customers. (1) Check products ahead of delivery; (2) Keep costumers informed about the delivery process. 3. After-sale services We promise excellent after-sale service! (1) Assist clients to prepare for the first construction scheme; (2) Install and debug the equipment; (3) Train the first-line operators on site; (4) Take initiative to eliminate the troubles rapidly at site; (5) Provide maintenance for big items. And other rational requirement brought up by our clients.

Contact us if you need more details on Hammer Crusher For Mining. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Hammer Crusher Price、Vertical Hammer Crusher. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Crushing And Screening Machine > Crushing Machine