Model NO.: SYS 35-1200 Current: Alternating Current Application: Welding Frequency: 35kHz Dimensions: 130*250*415mm Color: Blue Warranty: One Year Function: Plastic Welding Transport Package: Carton Origin: Zhuhai Type: Plastic Welders Model: Sys 35-1200 Brand Name: Lingke Welding Area: 1-50mm Weight: 6kg Feature: Non-Toxic Certificate: Ce Trademark: Lingke Specification: 130*250*415mm HS Code: 8515809090 Industrial ultrasonic RInco generators for plastic welding

Features

Ideal design with ergonomics, ultrasonic trigger is on the hand grip

Capable for long time operation, max . ambient 300ºC. Suitable for LCD sputtering

Ideal for spot welding ,riveting and forming

Protected cable duct

Rugged construction for optimal sound propagation

Worked with STD generator, various output for choice

Air cooling unit is for option

Match with automatic machine

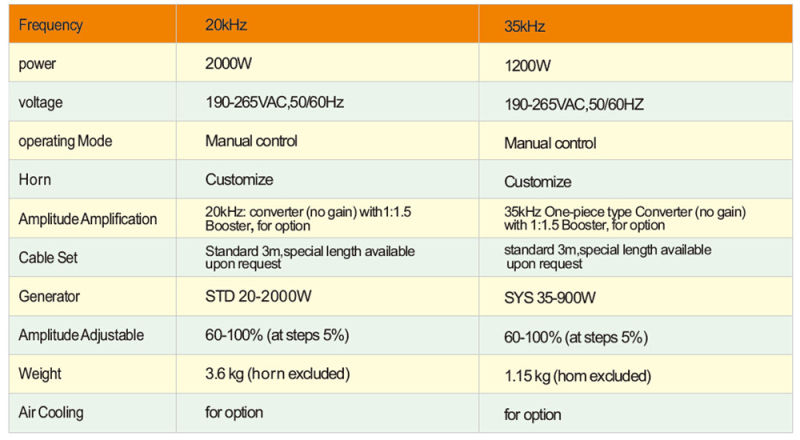

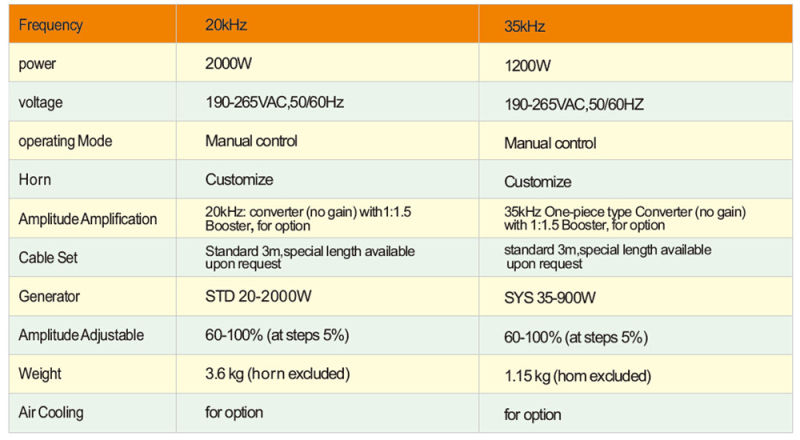

Specifications

Welding of plastic using ultrasonic Ultrasonic welding of plastic materials creates a molecular bond within the weld seam. Longitudinal vibrations in frequencies of 20 kHz, 30 kHz, and 35 kHz with tool amplitudes between 5 μm and 50 μm are introduced into the plastic materials under the action of force. Ultrasonic vibrations are focused by means of special design of the components or tools. This specific geometry within a component is referred to as energy director. The contact points in the joining area are actively molded by means of energy input to achieve elastic deformation. Friction occurring between the contact surfaces and within the molecule chains generates heat that causes the material to melt. Applicable all industry

Widely used in the automotive industry, electronic industry, medical industry, household appliances, woven apparel, office supplies, packaging industry, toy industry and so on. Automotive industry:

Highest weld quality: Vehicle parts must be joined to be tight, strong, dimensionally accurate and visually impeccable. Ultrsonic welding is a fast and economic solution for this complex task.

Hygiene industry : Laminating of nonwoven materials using ultrasonics

The general principle of ultrasonic welding can also be applied to nonwoven materials. The thermoplastic fibers are activated by mechanical vibrations thus melting and bonding in pre-defined patterns. A weld tool, referred to as Sonotrode, transmits the vibration into the nonwoven material. In industrial applications, ultrasonic frequencies between 20 and 35 kHz are common, with amplitudes (tool travel distances) of 10 μm to 50 μm. Processing of nonwoven materials is often performed in continuous processes at high web speed. By application of rotary tools, it is possible to achieve processing speeds of up to 800 meters/minute. A specifically engraved drum is used as welding, embossing, or cutting anvil. The contour of the anvil drum focuses the energy and precisely defines the weld spots required for the respective product.

Service 1)Analyse the different marketing conditions with customers and help to choose the machines which can save the investing cost and create quicker and more profits.

2) Help customer to training the technicians in our factory .

3)Any after-sell service problem will give feedbacks within 2 hours.

4)All the products we send out promise lift long after-sale service.

5) more professional.

FAQ

1.Are you factory?

Yes,lingke is located in zhuhai,near Macao,guangdonrg,with 20 years ,selling

Ultrasonic Plastic Welding Machine,

spin welding machine,

Hot Plate Welding Machine,

ultrasonic cleaner.

2.What service will you provide when I come to China?

We will pick up you to our factory and help you to book the hotel.

3.How can you guarantee we receive a good quality?

We have a serious group of quality control from component to finish product.and we also have mature assemble lines and operation instruction.

4.Do you provide any help about the product operation?

English operation instruction and video will be available.

5.How about warranty?

One year warranty,and providing lifelong free technique consultation.

Contact us if you need more details on

ultrasonic plastic welding machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

Ultrasonic Welding Machine、

Ultrasonic Generator. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : ultrasonic generator